anionic/cationic/nonionic polyacrylamide powder (PAM) for water treatment as flocculant and coagulant

CAS No.: 9003-05-8

Packing: 25kgs/bag

Under the dual challenges of water scarcity and environmental pollution faced globally, sewage treatment, as an important part of protecting water resources, is receiving increasing attention. Polyacrylamide (PAM), as a high molecular weight polymer, plays an indispensable role in wastewater treatment due to its excellent flocculation and coagulation properties.

Basic characteristics of polyacrylamide (PAM)

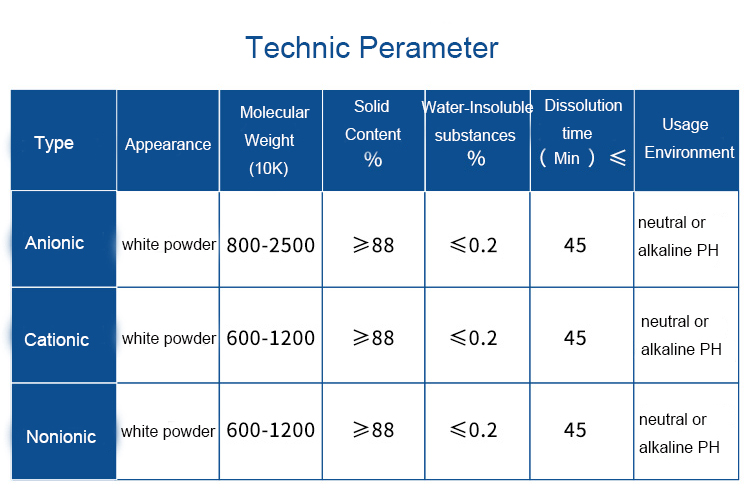

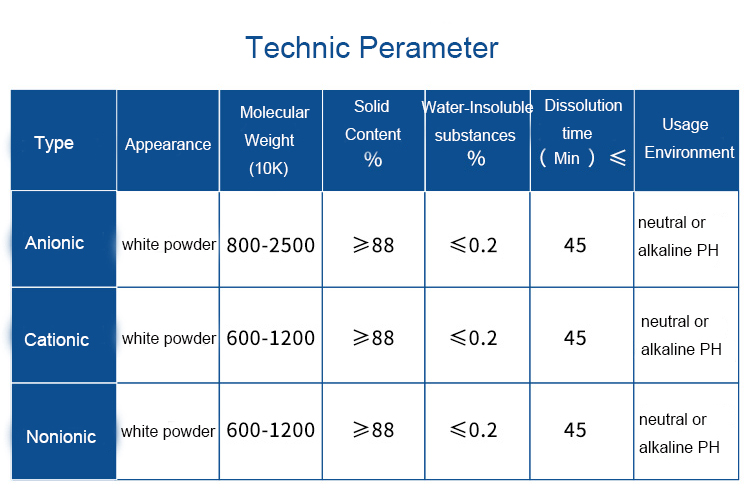

Polyacrylamide is a non-ionic or anionic or cationic water-soluble polymer with good adhesion and thickening properties. Its chemical structure enables it to interact with particles in water, promoting particle agglomeration. The molecular weight of PAM is usually between several million and tens of millions, and the difference in molecular weight directly affects its performance in wastewater treatment processes.

The use of PAM can significantly improve the efficiency of solid-liquid separation, while also reducing the cost of water treatment. Its main functions are manifested in the following aspects:

1. Flocculation: PAM can accelerate the collision of small particles, causing them to aggregate into larger flocs, thereby increasing the settling speed of solid particles in wastewater.

2. Thickening effect: By increasing the viscosity of water, PAM can effectively improve the dispersion state of solid particles, which is helpful for subsequent treatment processes.

3. Coagulation and precipitation: The anionic form of PAM can combine with positively charged particles in water to form larger precipitates, further improving the efficiency of wastewater treatment.

The main role of polyacrylamide in wastewater treatment

1. Sludge dewatering

Dehydration of sludge has always been an important and time-consuming task in the process of sewage treatment. The traditional sludge dewatering method has low efficiency and is prone to secondary pollution. Using PAM for sludge dewatering can effectively improve dewatering efficiency and reduce sludge moisture content. PAM improves the formation performance of filter cake by enhancing the cohesion between sludge particles, forming larger particle clusters. In practice, using PAM dewatering equipment can reduce sludge volume and reduce the workload of subsequent treatment compared to traditional equipment.

2. Sewage flocculation

In the primary stage of sewage treatment, wastewater contains a large amount of suspended solids and colloidal substances. If these substances are not treated, they will seriously affect the clarity and water quality of the water. Therefore, the introduction of PAM can serve as a flocculant, which, through its unique chemical properties, aggregates these tiny particles together to form larger flocs, allowing them to settle or float to the surface, thus achieving the goal of water purification. Especially in areas with severe pollution such as chemical wastewater and printing and dyeing wastewater, the application of PAM is more significant.

3. Industrial wastewater treatment

In the process of industrial wastewater treatment, many enterprises face high loads of sewage discharge and also need to strictly comply with environmental regulations. The important role of PAM in industrial wastewater treatment is mainly reflected in the improvement of regulations and the enhancement of sedimentation efficiency. Whether in electroplating, papermaking, or food processing industries, PAM can help companies reduce the cost of wastewater treatment in the production process and ensure that their discharge standards are within compliance.

Application of silica sol in papermaking industry: which paper types are more suitable

Application of silica sol in papermaking industry: which paper types are more suitable The functions of PEO in papermaking

The functions of PEO in papermaking 20 tons of drainage agent for Lao's customer starts shipping

20 tons of drainage agent for Lao's customer starts shipping Yinq New Materials made a successful participation at PaperExpo Shanghai 2025(China International Paper Technology Exhibition and Conference)

Yinq New Materials made a successful participation at PaperExpo Shanghai 2025(China International Paper Technology Exhibition and Conference) Precautions for adding wet strength agents in papermaking

Precautions for adding wet strength agents in papermaking Yinq will be present at Paper Expo Shanghai 2025

Yinq will be present at Paper Expo Shanghai 2025 Yinq made a brilliant appearance at Paper Vietnam 2025----Vietnam International Paper Exhibition

Yinq made a brilliant appearance at Paper Vietnam 2025----Vietnam International Paper Exhibition Yinq (Guang Dong) New Materials Shines at Paper Expo China 2025, Driving Innovation in Paper Chemicals

Yinq (Guang Dong) New Materials Shines at Paper Expo China 2025, Driving Innovation in Paper Chemicals

Home

Home products

products News

News Dial

Dial