Defoamer for Paper Industry

- 2024-12-25

- 58

- Yinq (Guang Dong) Imp & Exp Co., Ltd.

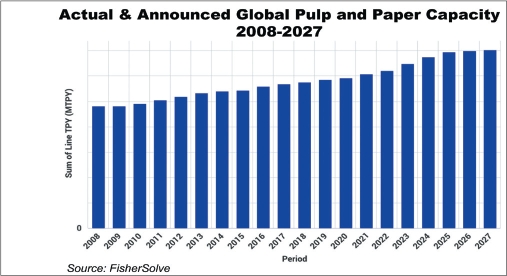

In the papermaking industry, defoamers play an indispensable role. With the rapid development of the papermaking industry, the requirements for paper quality are also increasing, and defoamers are one of the key factors for high-profile paper quality stability and improved production efficiency.

1. Foam problems in papermaking process

During the papermaking process, foam is easily generated due to operations such as stirring, pumping and water adjustment of the slurry. These foams not only occupy the space inside the equipment and reduce the effective volume of the equipment, but also affect the uniformity and smoothness of the paper. In severe cases, they may even cause paper breakage or holes. Effective control of foam is essential for the smooth progress of the papermaking process.

2. Principle of action of defoamers

Defoamers mainly eliminate foam by destroying the stability of the foam. It can form a thin film on the surface of the foam, reduce the surface tension of the foam, and make the foam unstable and break. Defoamers can also penetrate into the foam, destroy the elasticity of the foam, and make it burst quickly.

3. Selection and use of defoamers

When selecting a defoamer, factors such as its chemical stability, compatibility with papermaking pulp, and environmental impact need to be considered. Different types of paper machines and different pulp formulas may require different types of defoamers. Paper mills should choose suitable defoamers according to their own process characteristics and requirements.

During use, the amount of defoamer added is also a factor that needs to be carefully controlled. Too much or too little addition may affect the defoaming effect. Usually, the defoamer is added during the mixing or pumping of the pulp to ensure that it is evenly distributed in the pulp.

4. The importance of defoamers

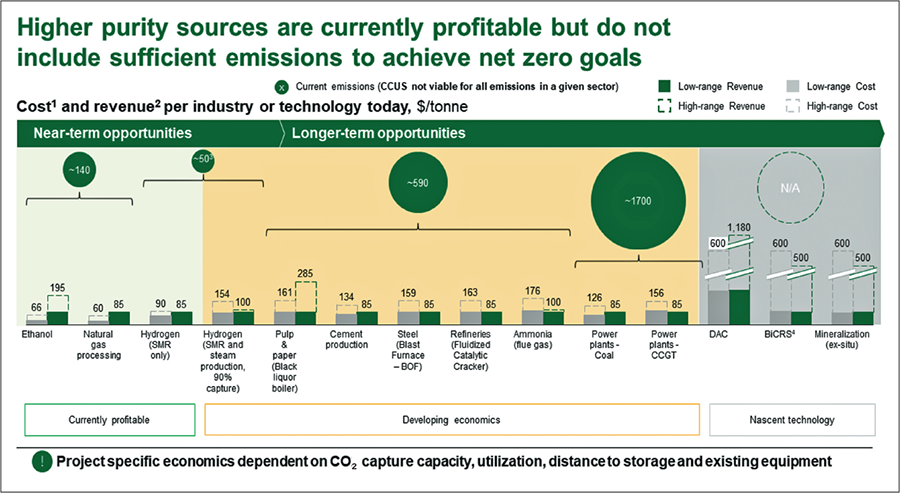

The importance of defoamers in the papermaking process cannot be ignored. It can not only improve the quality and output of paper, but also reduce equipment failures and maintenance costs. The use of defoamers also helps paper mills save energy, reduce emissions and protect the environment.

With the continuous advancement of science and technology and increasingly stringent environmental protection requirements, the demand for defoamers in the papermaking industry will be more urgent in the future. The development of efficient and environmentally friendly defoamer products will become an important guarantee for the sustainable development of the papermaking industry.

5. Development trend of defoamers

With the continuous development of the papermaking industry, defoamers are also constantly improving and optimizing. In the future, defoamers will pay more attention to environmental protection and sustainability, reducing pollution and impact on the environment. The performance of defoamers will also be more excellent, able to quickly and effectively eliminate foam, and improve the stability and efficiency of the papermaking process.

With the widespread application of intelligent and automated technologies, the addition and control of defoamers will also be more precise and intelligent. Through intelligent control systems, the amount of defoamer added can be monitored and adjusted in real time to ensure the popularity of the defoaming effect.

6. Conclusion

Defoamers play a vital role in the papermaking process. It can effectively solve the foam problem in the papermaking process, improve the quality and output of paper, reduce equipment failures and maintenance costs, and promote the sustainable development of the papermaking industry. In the future, with the continuous advancement of science and technology and increasingly stringent environmental protection requirements, defoamers will continue to be improved and optimized, injecting new impetus into the development of the papermaking industry.

网站首页

网站首页 产品中心

产品中心 新闻资讯

新闻资讯 一键拨打

一键拨打